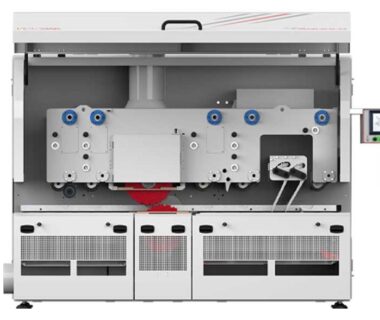

2-shaft Multi-blade SQUALO 420 Circular Saw: The reliability you are looking for

The 2-shaft Multi-blade SQUALO 420 Circular Saw has a maximum working width of 400mm and a maximum height of 200mm.

State-of-the-art for technologies used, it is indispensable in a modern sawmill, ideal for optimizing the production of sawn timber, strips, squares, profiles, trimmed boards, prisms, tablets, elements for pallets.

TECHNICAL SPECIFICATION:

Conveyor belt width mm 420

Input roller conveyors width mm 410

Output roller conveyors width mm 510

Max. saw unit width mm 390

Max. cutting height mm 200

Min. working length mm 800

Max. clearance width mm 700

Knife shaft diameter mm 60

Max. circular blades diameter mm 450

Blade hole diameter mm 80

Feeding speed m/min. 3 – 36

Compatible and combinable with our products (such as the pneumatic roller conveyor), the 2-shaft Multi-Blade SQUALO 420 is ready for your challenges!

Many reasons to choose our 2-shaft Multi-blade SQUALO 420:

- from the smallest to the largest, all our machines are designed with advanced, innovative and technological construction systems;

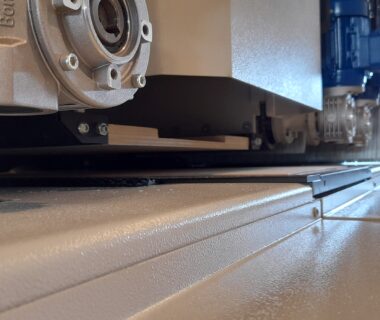

- special carpet in ductile iron with a new design and easy to maintain;

- Floor interrupted in the cutting area, to avoid cutting it, since it remains one of the most expensive parts of the machine;

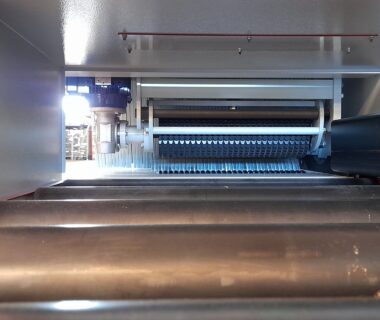

- feed with special rollers to work at high speeds;

- no “witness” with the cut on the Bi-tree;

- total operator safety as there are no metal-metal collision points between the introducer and the belt, and has 2 splinter guard barriers and 2 backstop barriers according to the latest directives;

- Top of the class for silence: it has a system where the motor is anchored that absorbs the inertia of the same; A perfect workmanship guarantees a non-welded structure, but pinned and bolted, anti-deformation: practically a do-it-yourself, with total elasticity, absorbing all work stresses and vibrations;

- All mechanical parts are easily accessible for simple and convenient maintenance;

- Rich control panel for easy and safe work;

- Ammeters in sight for motor absorption control;

and also:

- Inverter to prevent the wood-blade ratio from being exaggerated, without causing any damage, safeguarding the transmission components;

- Special steel shaft, centesimal ground, with balancing of the same at 4,000 revolutions;

- Large diameter blade holder shaft to avoid stresses of the same;

- Hard aluminum spacer rings to avoid rust formation in the case of wet wood processing, in addition to the supply of very low thickness steel rings for sharpening correction;

- Special high precision ring nut, unscrewing, and special key for easy opening;

- Independent presser with structure anchored on two chromed stems for easy and precise handling by means of trapezoidal screws and thick nuts, protected by dust caps and wood splinters;

- Perfect parallelism of the pressure group on the work surface;

- It is considered the first in its class ever, with a 20/30 mm steel structure, where all the mechanical parts are anchored;

- Unbeatable quality / price ratio;

- Cutting-edge technology with over 35 years of direct experience in biting We are Trademak, whoever works with our machines will never buy anything from the competition. 100% RELIABILITY and WARRANTY

Take a look at our single-shaft multiblades

Visit us on Machineseeker too!

Link video: https://www.youtube.com/watch?v=oFg69ColRO8